UG metal in Hedensted produces sand castings for commercial and industrial customers

From our address on Blæsbjergvej, we have specialists in all types of sand casting, from the production of models, sand molds, sand cores and the casting process itself. We deliver both nationally and internationally, and our customers range from small engineering companies to large international companies. We produce everything from impellers to valves and pump housings. See examples of items produced with sand casting under products.

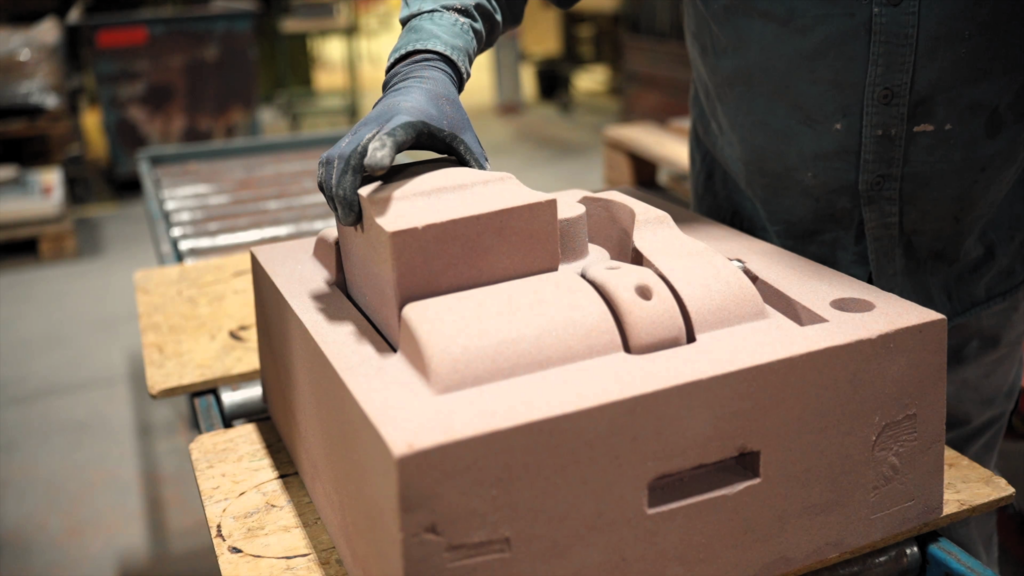

Metal sand casting is done using self-hardening sand. The model of the cast part is formed via hand molding, where the mold itself is manually made in a mold box.

The sand mold is made as two halves that are glued together. Any core for cavities in the finished molded part is placed in the sand mold before gluing.

In the case of sand casting of less complicated parts and parts without a core, the mold can also be made by hand molding according to the original part.

We use sand casting to cast the metals aluminum, gunmetal, bronze and brass, as well as Cu alloys, often in series sizes of 1-100 pieces. This is why this process is particularly suitable for prototypes and test series – both small and medium-sized series.

Each mold is manufactured individually, which means that even the most unique product can be cast.

We often start projects and new parts with sand casting. It’s an easy and relatively inexpensive method to initiate, and it produces uniform and detailed parts.

For larger series productions in aluminum, it is often recommended to switch from sand casting to die casting with fixed molds, as it saves on overall production time.

See examples of sand casting under products. Learn more about the mechanical properties of alloys here: Alloy overview

The metal is melted in induction furnaces. This minimizes the risk of gas in the melt.

The forming is done manually. The mold is blackened to improve the surface of the casting. In sand casting, inlet systems can be changed relatively easily when changing alloys.

At UG Metal, we manufacture high-quality metal castings, including aluminum:

– Aluminum

– Bronze

– Tin bronze

– Aluminum bronze

– Brass castings

We work with the following casting methods:

– Shell-mould casting

– Sand casting

– Gravity die casting

Yes, we have! At UG Metal we are DS/EN ISO 9001:2015 and DS/EN ISO 14001:2015 certified. If you would like to read more about our certifications, please visit our certifications in the buttom of the page.

UG Metal has more than 40 years of experience and has always been family-owned and is now run by the 3rd generation. This means, that we have built up an enormous know-how in metal casting, especially in Shell-mould casting, sand casting and gravity die casting.

Our company details at UG Metal are:

Th. Udengaards Metalstøberi A/S

Blæsebjergvej 44

8722 Hedensted, Denmark

CVR: 51686519

You can easily get in touch with UG Metal if you need help or have questions about our solutions and products. Send us an email at ug@ugmetal.dk or call us on +45 75 89 16 22.

Th. Udengaards Metalstøberi A/S

Blæsbjergvej 44

8722 Hedensted

CVR: 51686519

Copyright © 2024 UG Metal. All rights reserved.